San Diego has become a central player in the game of space exploration with dozens of local companies playing a hand in NASA's first manned mission in more than 50 years.

The last astronauts set foot on the Lunar surface in 1972 -- astronauts Gene Cernan and Harrison Schmitt -- but the Artemis moonshot program intends to revive space exploration by putting the first woman and the first person of color on the Moon, and eventually to Mars.

It's a huge endeavor for the U.S. space program, and one that requires the help of Americans across the country. NASA enlisted the help of hundreds of companies, including more than two dozen in San Diego County, to help build and test the systems that can get humans into space, making the Artemis mission a truly collaborative effort.

NASA's Artemis Mission

As astronaut Reid Wiseman said, "This is not NASA doing this. This is the United States of America doing this program, the Artemis program, and there are companies all across our country that have a part in it. So there is kind of this wave of excitement being generated just by saying, 'We're going back to the moon.'"

Some San Diego companies provided NASA and their partners with the tools and components needed to complete various aspects of their program. Others had larger roles in producing the technology used for the missions.

Click through the map below to see the local companies that helped NASA on its mission to send humanity back to space.

Click here to learn more about each of the segments of NASA's Artemis mission

Meet 6 San Diego Companies

With Ties to NASA's Artemis Mission

Out of the more than two dozen local companies with ties to NASA's Artemis mission, NBC 7 spoke with eight about their involvement. While most couldn't disclose all the details of their highly secretive projects, all expressed excitement for being involved in NASA's next big leap for mankind.

Take a peek at their contributions below:

Advanced Test Equipment Corporation — Sorrento Valley

Tell us a bit about your Company.

Advanced Test Equipment Corporation has been in business for the last 40+ years, headquartered in Sorrento Valley, and provides a wide variety of unique test equipment across a wide variety of markets, from Aerospace, Automotive, Defense, Medical, Utilities and more.

How did your company support NASA's Artemis Mission?

ATEC supports the Electromagnetic Compatibility (EMC) testing that happens on the Orion spacecraft at the Neil A. Armstrong Test Facility in Ohio. To accomplish this testing, a lot of very expensive equipment is needed, and we provide it quickly as a rental. We are involved with both the testing of Orion as mentioned before, as well as the launch at Kennedy Space Center. We have provided a different test solution where the space center has a spectrum monitoring system to detect any interfering or rogue signals in the area, such as ones that come from drones.

How does your technology work?

The equipment we provide for testing Orion simulates the spacecraft's immunity to high levels of electromagnetic radiation. This is very important to ensure that all the electrical systems on board will operate properly when the actual launch takes place.

What does being a part of this mission mean to the company?

It is a great accomplishment, in terms of being able to help NASA quickly and economically, by saving them time and money on very expensive equipment, without having to wait the long lead times we are experiencing today.

This has been something we have supported NASA with for 5+ years, as well as their prime subcontractor Lockheed Martin with a variety of different applications, and we are proud to support them with their many unique requirements.

Valhalla Scientific, Inc. — Poway

Tell us about your company.

Valhalla Scientific has been in business since 1971 and our instruments have been vital to many space missions for decades including the Artemis Mission, the Mars Rover and the James Webb Telescope. At our core is a passion for precision, an eagerness to develop meaningful business relationships by delivering consistently superior customer service, and a commitment to quality.

We do what we do because we love what we do. And we are proud of being a part of the development of emerging technologies that will allow us and future generations to explore and make new discoveries in the field of space and aviation. Nothing makes us prouder then being part of these great endeavors.

How did your company support NASA's Artemis Mission?

We supply Igniter Testers (Fail-Safe Ohmmeters) to Nasa JPL, specifically, our Alpha-4314 Series. Most of our involvement is during the testing phase to ensure that the release devices of the flight separation mechanisms will function properly.

How does your technology work?

Our Alpha 4314 Series Igniter Testers are used all across the aerospace industry. The equipment is designed to test the readiness of EEDs (Electro-Explosive Devices) without setting them off.

The EEDs set off controlled explosions during separation phases of the different parts of the rocket. Our Igniter Testers are vital to test that these devices detonate precisely when required – not while testing, preventing loss of time, money and potentially human lives.

The Alpha 4314 Digital Igniter Tester is an ohmmeter, which has been specifically designed for safe resistance testing on many explosive devices. We have designed our Alpha 4314 to guarantee both the readiness of the EED and the safety of the operator. The Alpha 4314 is equipped with redundant, dual fail-safe, current-limiting circuitry that ensures the instrument’s test currents cannot exceed the trigger amount. Those working with explosive devices can have peace of mind knowing that the redundant fail-safe limiting circuitry will physically prohibit accidental ignition in the event of equipment failure.

What does being a part of this mission mean to the company?

We are extremely honored of our contribution to the mission and amazed that our small business can have such a critical role. We follow NASA missions closely and take much pride in the small part we play in space exploration.

Applied Composite San Diego — Oceanside

Tell us about your company.

Applied Composites is a leading provider of complex composite components, assemblies, engineering and tooling to the aerospace, defense, and space systems markets.

How did your company support NASA's Artemis Mission?

Applied Composites San Diego fabricated the lightweight composite ogive panels and fillets that comprise the outer skin and structure of the Launch Abort System (LAS). The LAS is designed to protect the crew capsule and astronauts should a problem arise with the rocket during launch, quickly separating and propelling itself away from the failing rocket. The ogive panels and fillets connect the launch abort rocket motors to the crew capsule and protect the crew capsule during the high-speed separation to safety.

Applied Composites also manufactures the compression pad connections between the European Space Agency (ESA) service module and the Orion crew module. These joints need to sustain extreme launch forces and are a critical component of the Orion capsule’s heat shield upon reentry. When Orion returns to Earth, our product will burn up, keeping Orion and our astronauts safe.

How does your technology work?

The ogive panels, fillets and compression pads are critical to protecting the crew capsule and crew from the harsh environment of launch and reentry. Additionally, as the panels are part of the Launch Abort System (LAS), they are an integral part of this cutting-edge safety technology developed jointly between Lockheed Martin and NASA. The panels are designed and fabricated to be both very lightweight as well as very strong. The compression pads, which form part of the Orion heat shield, are created through a unique process developed by employees at Applied Composites San Diego in conjunction with Lockheed Martin and NASA. The design provides extreme strength and thermal protection while allowing it to burn up when Orion returns to Earth. In addition to fabrication, extensive testing was conducted at Applied Composites San Diego to ensure that the components achieved or exceeded the stringent strength requirements.

What does being a part of this mission mean to the company?

There is no higher responsibility in this program than the protection of human life in space flight. The team at Applied Composites San Diego takes enormous pride in meeting the high standards of excellence required to deliver on this responsibility. There are few opportunities like the Artemis missions that inspire in all of us a sense of adventure, exploration and remind us of the scale of what mankind can achieve when focused on a common goal. It’s missions like this that inspire the next generation of scientists, engineers, and mathematicians. Helping to call upon the youth of today to pursue STEM programs and grow one day to be the future leaders and innovators of industries such as ours is a very important part of serving the aerospace industry, our customers, and their customers. It is a privilege to play such a key part of the Artemis missions.

It’s an exciting time to be a part of the aerospace industry. We have already delivered the next set of composites for Artemis II and are hard at work on the components for Artemis III. The space launch market is growing rapidly, as are satellite structures. People are back to traveling again in increasingly record numbers and the 10-year outlook for both commercial and government space exploration is extremely strong. And, as we’ve all seen in the news, the importance of equipping our troops, and those of our allies, with the very best in defense technology is a critical part of national security and global stability. There are many exciting opportunities right now to join our team and be a part of historic and heroic missions like Artemis, as well as great things yet to come in aerospace, space and defense.

ATA Engineering — Sabre Springs

Tell us about your company.

ATA Engineering, Inc. is a small business that provides test- and analysis-driven design services for aerospace, defense, themed entertainment, consumer products, and industrial equipment.

How did your company support NASA's Artemis Mission?

Over the past decade, ATA Engineering has contributed to several key components of the NASA Artemis I mission, including the Orion spacecraft, the Space Launch System (SLS), and the mobile launcher. We participated directly with the NASA centers as well as with aerospace prime contractors in support of this mission.

ATA directly supported modal tests of the mobile launcher as well as of the integrated system once assembled at NASA’s Kennedy Space Center. We then participated in efforts to update the computer models to better fit the modal test results, a step that is essential to developing the required confidence in the success of the flight.

ATA Engineering’s contribution was at the system level, but the computer models that were validated through this effort are most important in ensuring a successful ascent of the SLS through Earth’s atmosphere.

How does your technology work?

For ATA Engineering’s NESC support, the technology to perform modal tests and adjust the computer models to match the results of those tests is applied throughout the aerospace industry. It is well accepted as the standard for validating the accuracy of models for all NASA missions, but particularly so for something as complex as the Artemis I mission.

What does being a part of this mission mean to the company?

The opportunity to contribute to the Artemis I mission is extremely rewarding. ATA Engineering is proud to be a part of any NASA mission, but we are particularly grateful to be a part of the Artemis I mission because of its complexity and scale. Our work will help to minimize risk and ensure a successful flight. The opportunity to support incredible projects like this is the reason that many of us at ATA decided to become engineers and explore our universe in new ways. We thrive on the ingenuity needed to overcome intense challenges through the achievement of practical solutions. Our team is honored to contribute to such an important NASA mission.

Rayotek Scientific — Sorrento Valley

Tell us a bit about your Company?

Rayotek Scientific, Inc., a San Diego-based company, was founded in 1992 and has evolved into a multi-national corporation with extensive expertise in the engineering and fabrication of glass, sapphire, ceramic, metals and refractory products for high-tech, high-stress applications. Located just east of University Town Center, Rayotek operates in a 20,000 sqft state-of-the-art facility.

Over the last 3 decades, Rayotek has become a global leader in the engineering, testing and manufacturing of fused silica and acrylic space and deep sea vehicle windows.

How did your company support NASA's Artemis Mission?

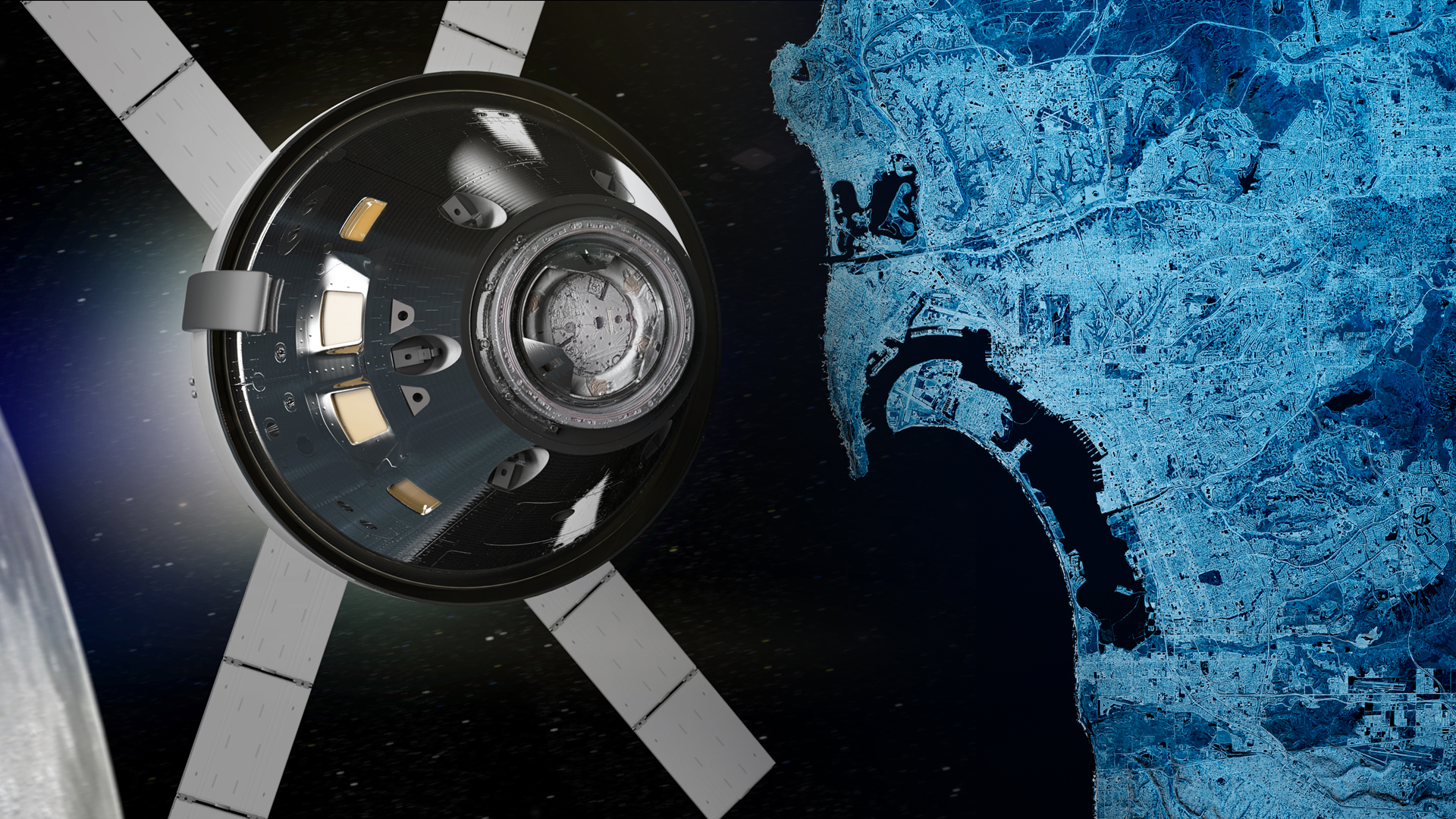

Rayotek provides the engineering, manufacturing and extensive testing of the windows installed on Orion, NASA Artemis’ crew exploration vehicle.

Rayotek is involved in the Orion transparency portion of the program, NASA’s crew exploration vehicle. The Orion capsule is capable of supporting a crew of six and Rayotek is responsible for the manufacture of durable, safe windows that enable viewing of earth, the moon, and the cosmos while supporting a safe living environment during the mission and through re-entry.

How does your technology work?

Rayotek uses proprietary fabrication technologies that greatly reduce the risk of windows breaking, even when subjected to the rigors of launch, the vacuum of space, and re-entry. Rayotek’s optically clear windows provide a safe, direct and unobstructed view into the wonders of space, both for observing the cosmos, and the more practical use of inspecting the outside of the spacecraft in-flight. The camera’s on the inside of the vessels are currently recording what our future astronauts will see on upcoming manned flights.

What does being a part of this mission mean to the company?

Being part of this mission is exciting on several levels! First, it’s a huge honor and a testament to NASA’s trust in Rayotek’s capabilities to be involved in such a high-profile program. We are a small 30-person company doing big work! In addition, being involved in space transportation/exploration and the cutting-edge possibilities feels like important work in the world; we are proud to be part of this program. Several of our staff attended the Orion EFT-1 and Artemis launches and the feedback from each and every team member was the same, being surrounded by hundreds of people who participated in the building of the next generation of space vehicles is an awe-inspiring and once-in-a-lifetime opportunity.

Mouser Electronics, Inc — El Cajon

We are an authorized, global distributor for semiconductors and electronic components and service over 650,000 customers worldwide from our Global Distribution Center in Mansfield, Texas, including NASA and the world’s largest military/aerospace customers. We support NASA directly and also through lots of subcontractors who rely on Mouser as a coveted AS9100D-certified supplier for the aerospace industry.

Mouser helps secure the authentic, specialized electronic components for the aviation, space and defense industries. That would include many of the components used to build the SLS Rocket. We can’t say which specific components, manufacturers or orders are represented in the Artemis mission or the part of the rocket as that is confidential. Official confirmation would come from NASA. Mouser sells and distributes products from over 1,200 manufacturers, and we support innovation and are excited to help NASA with this mission.

Answers were provided by the companies involved and may have been edited lightly for grammar and punctuation.

What are the segments of the Orion program?

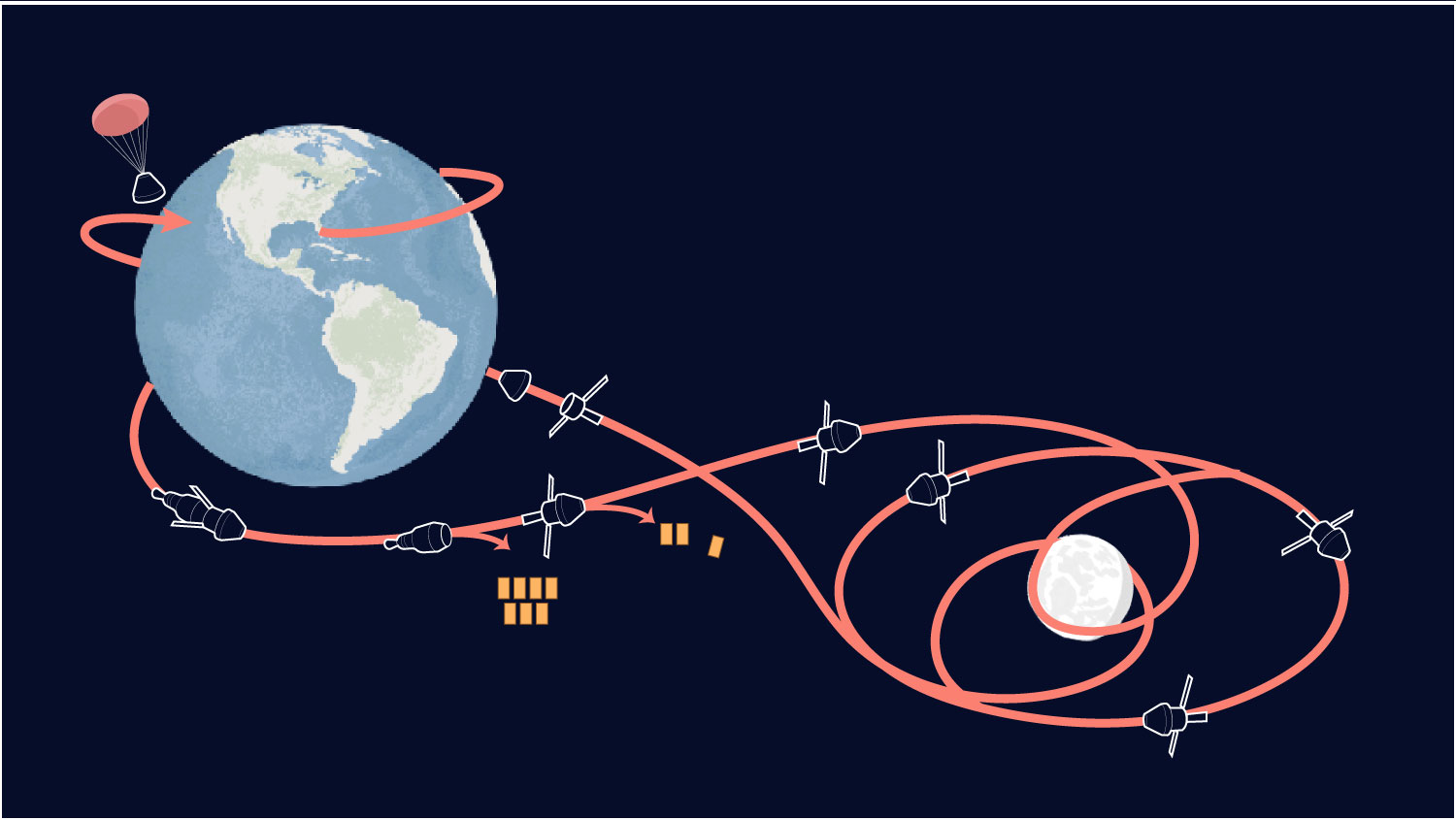

With such a huge endeavor ahead, NASA has split the tasks on hand into several different programs, each with a different role to support the overall Artemis mission. Here's what each of the programs do:

Orion: Companies that worked on the Orion program had a hand in building, developing and testing the capsule that will one day carry NASA astronauts to space. Work on this mission includes building the heatshield that will protect astronauts from burning up as they re-enter Earth's atmosphere.

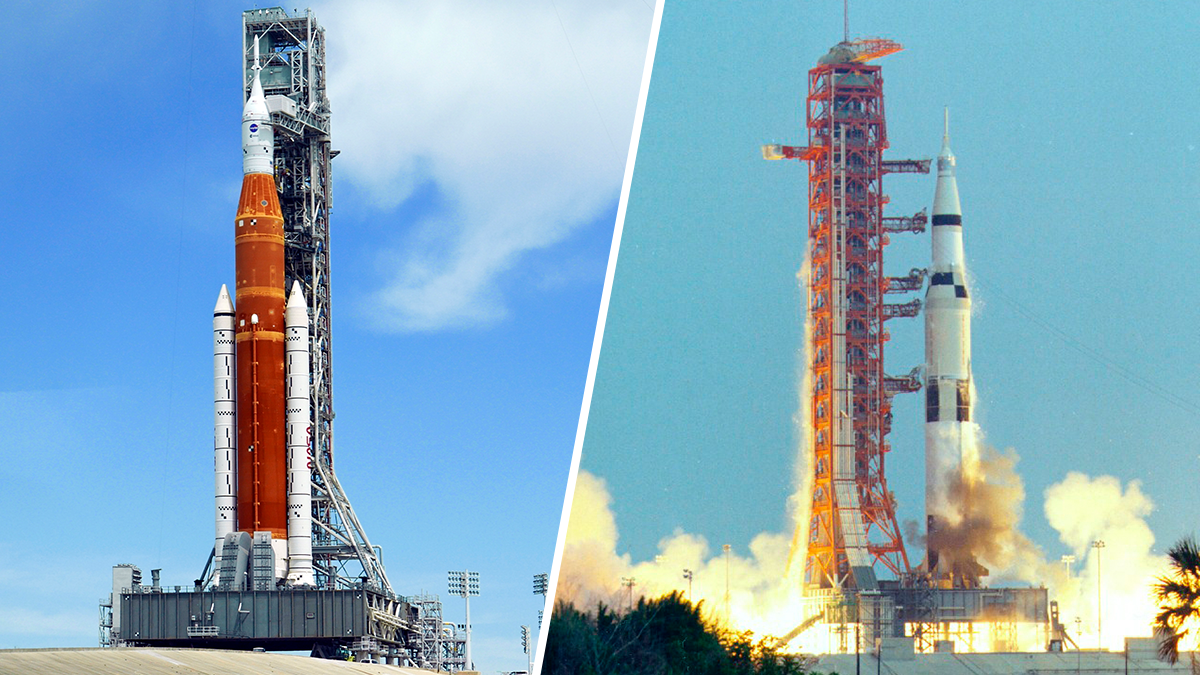

The Space Launch System: NASA's new moon rocket produces 8.8 million pounds of thrust and can go from 0 to 100 within seconds. It's the most powerful rocket ever built by NASA and required a team of companies to build, including several in San Diego.

Exploration Ground Systems: This is the team that supports facilities on the ground to launch and recover NASA's spacecraft, including the launch platform at the Kennedy Space Center.

Gateway: The Gateway will one day be an outpost orbiting the Moon that will provide astronauts with access to the lunar surface. Think of an orbiting home for astronauts on months-long journeys in space. Both U.S. companies and international partners have a hand in creating these living quarters that will also include labs for research.

Human Landing System: While Orion will get astronauts to space, it won't be able to land on the moon. This Human Landing System will provide the transportation between Gateway and the lunar surface. With the HLS, Americans will again land on the moon for the first time in 50 years.

There are several other programs in progress for NASA Artemis Mission. To get a breakdown of each, click here.